Ain’t No Sad Songs On A Banjo

Photos/Story: T-Bone

For many of us gear heads half the joy of working on our cars is actually driving our cars. Who’d a thunk it? Well, when you are behind the wheel we gaze over the big circle on the road ahead. In-fact, in driving school they say to “aim high” to help anticipate any challenges in the road ahead. With that mantra we forget about the jewel right in front of us. We look right over it and sometimes right through it.

We have a nice Lecarra Mark 9 Double Slot wheel on our ’56 Fairlane “Riff Raff”, which has been on the car since we bought it. Nice, but we were looking for something a bit different as we transform it from a street rod to a custom. The GT Performance Banjo wheel is just the ticket. What a jewel.

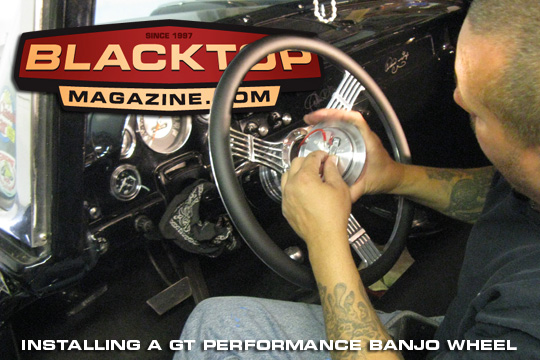

The wheel came in one box and the hub and horn button came in another. GT has a variety of horn buttons to choose from. We chose the circle style to compliment the banjo lines. This wheel is an inch larger in diameter at 15.5” and 1” dish. After centering the front wheels, disconnecting the battery and removing the old wheel the installation was pretty simple. Here’s how it goes:

Step 1: Apply a thin layer of grease (supplied in little capsules) to the copper contact ring on the bottom of the hub. Billy rubbed it on with his fingers.

Step 2: Position the column sleeve with taper toward the front or end of column. Just slip it on at this point. Do not adjust or tighten at this time.

Step 3: Note the markings on the hub with two little dimples next to one of the 9 holes. Note red circle in photo 5 showing dimples. That’s the top. Slip the hub over the column with those markings at 12 O-Clock.

Step 4: Install shaft nut and tighten to 25/30 ft. lbs. We used a socket with a bit of muscle at the end.

Step 5: Install wheel onto the hub and secure with 9 screws with allen wrench provided. DO NOT OVERTIGHTEN, or you will strip out the hub.

Step 6: Adjust column sleeve so there is a 1/16” to 1/8” gap between sleeve and end of column. Basically, you don’t want it to rub on the end of the column. Tighten set screw with provided allen wrench.

Step 7: Connect wires to the bottom of horn button. Slightly wet the o-ring for easy installation. Press horn button on wheel keeping in mind not to kink horn wires.

Step 8: Reconnect battery and test horn button and turn signal cancellation.

Note: To remove horn button insert small non-marring plastic blad or screw driver between notch and wheel surface and carefully pry up to release.

Check out our quick install video on Blacktop TV.

It was as simple as that, now it’s time to go make a tune with this fine instrument in our hands. Get yours at www.GTPerformanceProducts.com